From Raw Material to World-Class Aluminum

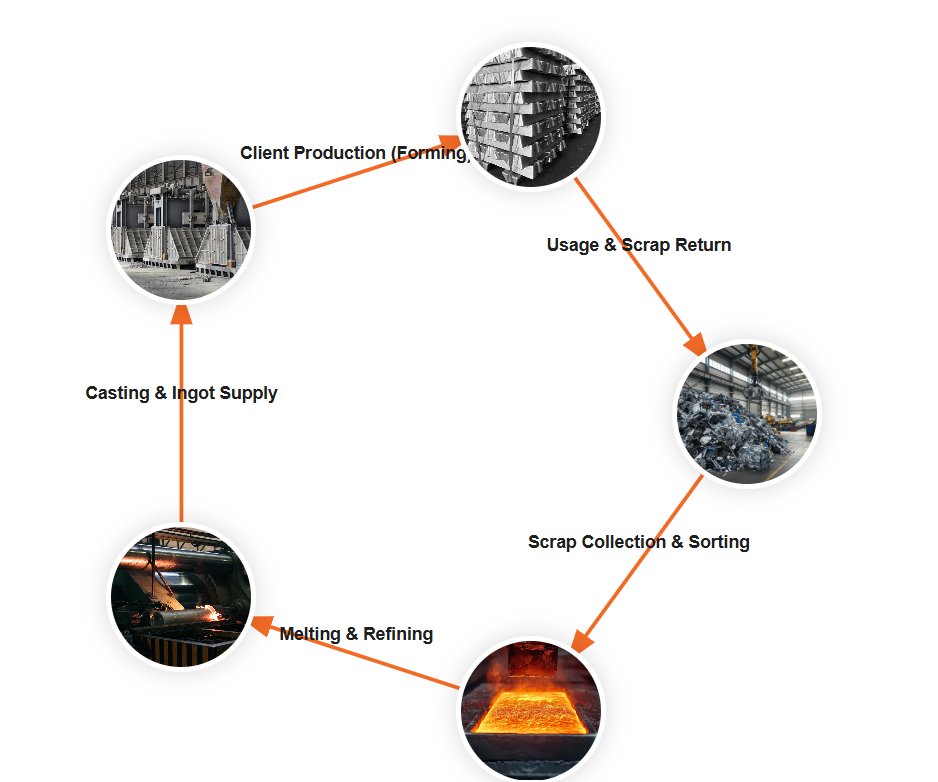

With over 10 years of experience, UMC Egypt transforms raw aluminum and recycled materials into high-quality products, guided by sustainability and precision at every step. Our state-of-the-art production park processes aluminum scrap and primary materials efficiently, producing more than 25,000 tons annually for global markets. Aluminum is melted in advanced furnaces, refined to meet strict quality standards, and all residues are fully recovered and reused, highlighting our commitment to environmental responsibility. The refined aluminum is then cast into ingots and supplied to clients for further forming, extrusion, or component manufacturing, ensuring consistent purity, performance, and quality.

Why Choose UMC Egypt Production

Premium Quality

Over 10 years of experience producing high-quality aluminum with precision and durability.

Advanced Technology

State-of-the-art machinery ensures efficient, precise, and consistent production.

Sustainability

Eco-friendly processes with recycling and minimal waste, producing 25,000+ tons annually for global markets.